BioSafe Systems has endeavored to mitigate growers’ risks when it comes to preharvest food safety for years. Contaminated irrigation water can compromise an operation and incite potential recalls. The most common culprits threatening consumers’ food safety are the foodborne bacterial pathogens Salmonella enterica, and Escherichia coli (E. coli), specifically the Shiga toxin-producing E. coli (STEC). When these harmful bacteria contaminate water sources used for irrigating crops, they can potentially lead to food safety recalls and inflict incredible damage on growers, the public’s health, and consumers’ trust in a brand.

There have been several historic recalls in the food safety realm including a severe Escherichia coli O157:H7 outbreak in spinach in 2006 that affected the health of consumers in 26 states. In the case of the spinach recall, the E. coli outbreak was traced to a specific grower’s field in California where spinach cropland was cultivated in close proximity to a cattle ranch. The exact cause of the outbreak is hard to trace because there are so many variables in the environment that can carry pathogens through fields, which makes risk management strategies critical. Irrigation water is a potential avenue that can spread foodborne bacterial pathogens. Growers, shippers, and retailers know food safety recalls can result in many costs, including product loss, retrieval, disposal, and tarnished relationships with customers and distributors.

Food safety recalls initiate an extensive root cause analysis conducted by the FDA and in collaboration with distributors and growers to determine the potential hazard that may have instigated the contamination that resulted in the recall. While these investigations into the cause of the recall proceed, even a wrongful accusation can damage a brand’s reputation and consumers’ trust. USDA research suggests that the average cost of a food safety recall for a company is around $10 million. Growers have a greater responsibility to ensure the crops are grown in a manner that reduces potential environmental risks before products hit the retailers’ shelves for purchase.

Since joining BioSafe Systems, Dr. Sughroue has been working diligently with our research director, Dr. Vijay Kumar Choppakatla, and university researchers conducting lab tests and large-scale field trials to get SaniDate® 12.0 (a peroxyacetic acid (PAA) based product; EPA Reg #70299-18) EPA-registered for the control of foodborne bacterial pathogens in agricultural irrigation water. We knew early on that SaniDate 12.0 was very effective in controlling indicator organisms like generic E. coli and coliforms in preharvest source water used for irrigation. However, there was no official EPA protocol for manufacturers to use to determine a products’ ability to control foodborne bacterial pathogens in irrigation water.

After the 2006 outbreak in spinach, because there was no EPA-registered product for controlling human health pathogens in irrigation water, leafy green growers began using products approved for treating contamination like algae, fungi, water molds, and slime-forming bacteria. BioSafe Systems was already working to register a product that could do both.

In 2012, Virginia Tech published a paper analyzing how effective pesticides were in reducing plant and human health pathogenic bacteria in pesticide spray water, including BioSafe Systems’ PAA-based product OxiDate® 2.0. Two years later, Penn State conducted another study testing SaniDate 12.0’s control over E. coli in irrigation water. SaniDate 12.0 was found to reduce generic E. coli by 99.9999%. That’s a 6-log reduction when the minimum requirement by the FDA for human health pathogen claims on postharvest labels is a 3-log reduction.

Finally, in 2020, the EPA approved the FDA Efficacy Protocol (FDA source) for the reduction of foodborne bacteria in preharvest agricultural water. This allowed manufacturers to test products for the mandated 3-log reduction or 99.9% reduction in pathogens, which would allow this claim on their EPA-registered product for irrigation water treatment.

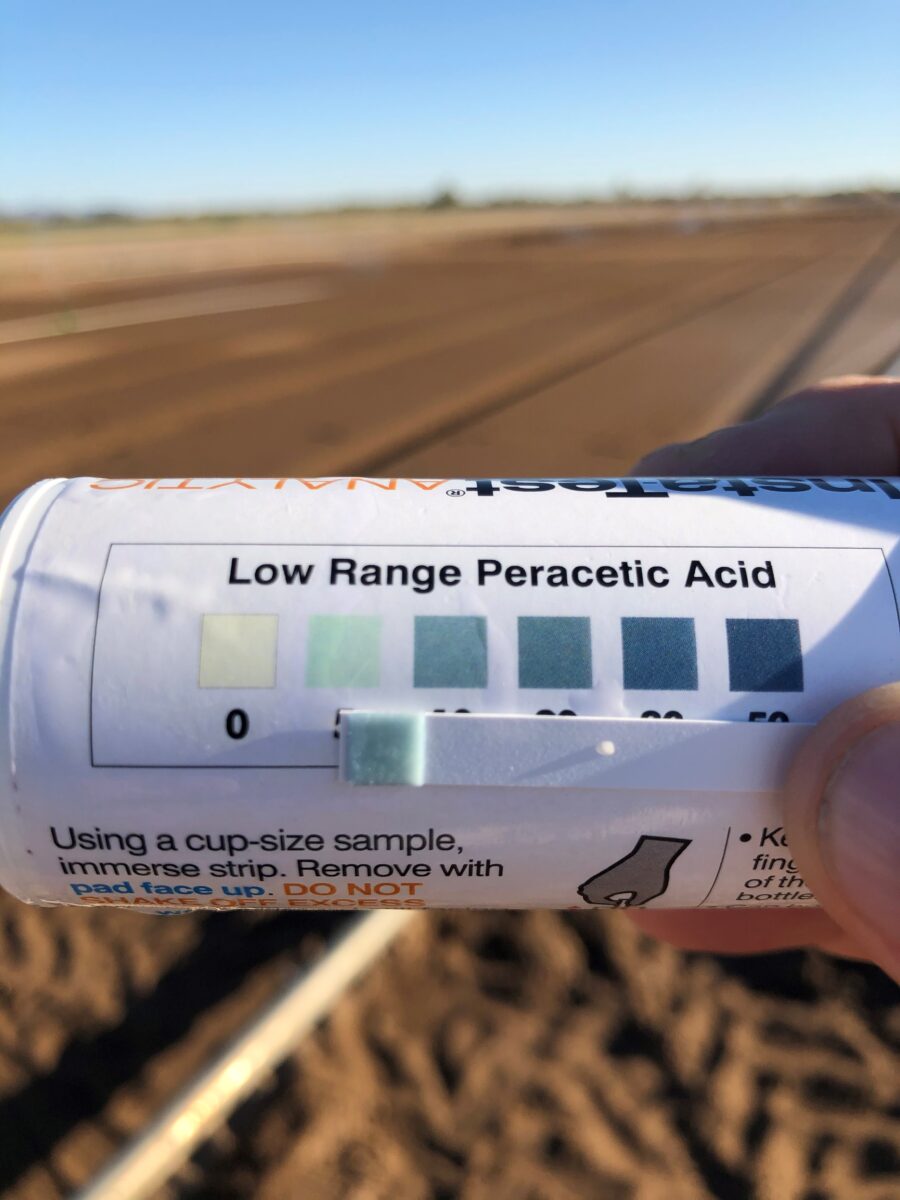

In 2018, in response to the romaine lettuce outbreak in Yuma, Arizona, Dr. Sughroue started working with Dr. Rock of the University of Arizona to conduct our own large-scale field trials. The research team injected non-pathogenic bacteria strain into irrigation lines of a fallow field followed by an injection of SaniDate 12.0 to better understand how to use SaniDate 12.0 to treat contaminated irrigation water effectively.

Dr. Sughroue conducting field trials in Yuma, AZ

Concentration levels of SaniDate 12.0 were taken at several places throughout the irrigation system. The samples illustrate how quickly and effectively SaniDate 12.0 controlled the bacterial strain, and which concentrated dose showed the best results. The goal is to update the SaniDate 12.0 label with provisions to control specific foodborne pathogens and help growers meet FDA, FSMA, and LGMA regulatory requirements. After accumulating robust data from several large-scale field trials over two years, it was time to submit SaniDate 12.0 for evaluation using the recently approved EPA Efficacy Protocol for the reduction of foodborne bacteria in preharvest agricultural water. SaniDate 12.0 easily achieved the minimum 3-log reduction of E. Coli and Salmonella for the claim to be submitted to the EPA for registration.

By July of 2023, Arizona approved a Special Local Needs (SLN) label for human health pathogen treatment (full press release here). In 2024, SaniDate 12.0 became the first EPA-registered product on the market labeled for preharvest irrigation water treatment to control foodborne bacterial pathogens (full press release here).

Dr. Sughroue emphasizes the importance of SaniDate 12.0’s versatility and its compatibility with nearly all commonly used agricultural inputs like fertilizers and other pesticides. The complete absence of phytotoxicity risk, when used at label rates, makes SaniDate 12.0 the superior choice for treating irrigation water. These chemical characteristics protect the plant health programs already in place and won’t damage crop development.

Dr. Channah Rock, Professor and Water Quality Specialist at the University of Arizona, who worked on the research with BioSafe Systems said, “The recent amendment of SaniDate 12.0 for treating preharvest agricultural water is an exciting advancement in the growers’ toolbox. It offers a valuable strategy to mitigate human health pathogens in irrigation water, enhancing food safety and reducing environmental risks.”

BioSafe Systems offers more than product solutions, including customized standard operating procedures for each step in the daily operation of treating irrigation water to ensure the desired residual ppm to control foodborne bacterial pathogens is being achieved. We’re a reliable resource for on-site training in applications and safety, offering customer support and troubleshooting guidance. BioSafe Systems’ long-standing commitment to preharvest irrigation water treatment reflects BioSafe Systems’ commitment to solving problems for growers.