What Makes BioSafe Systems the PAA Experts?

First and foremost, BioSafe Systems initiated PAA applications within agribusiness in the United States. Applying our proprietary chemistry to agribusiness was an innovative step that eventually helped shift the marketplace to accept this sustainable chemistry. As we’ve grown, we’ve been initiating research and accumulating data by partnering with universities and utilizing our own lab team to test our chemistry. We’ve brought in experts with varying specialties such as PhDs, and plant pathologists with unique knowledge linking their education to our PAA applications to corroborate our claims and show our credibility as PAA experts.

Growers find BioSafe Systems’ products effectively improve disease management when our broad-spectrum formulations are tank-mixed with systemic and residual active ingredients. The combination improves Integrated Pest Management (IPM) programs that can be stronger and more well-rounded to help reduce the risk of resistance. While we started our roots in horticulture, we have since expanded to accommodate multiple divisions with special emphasis on crop protection, sanitation, food safety, water treatment, and growing medium treatments.

The Power of Peroxyacetic Acid

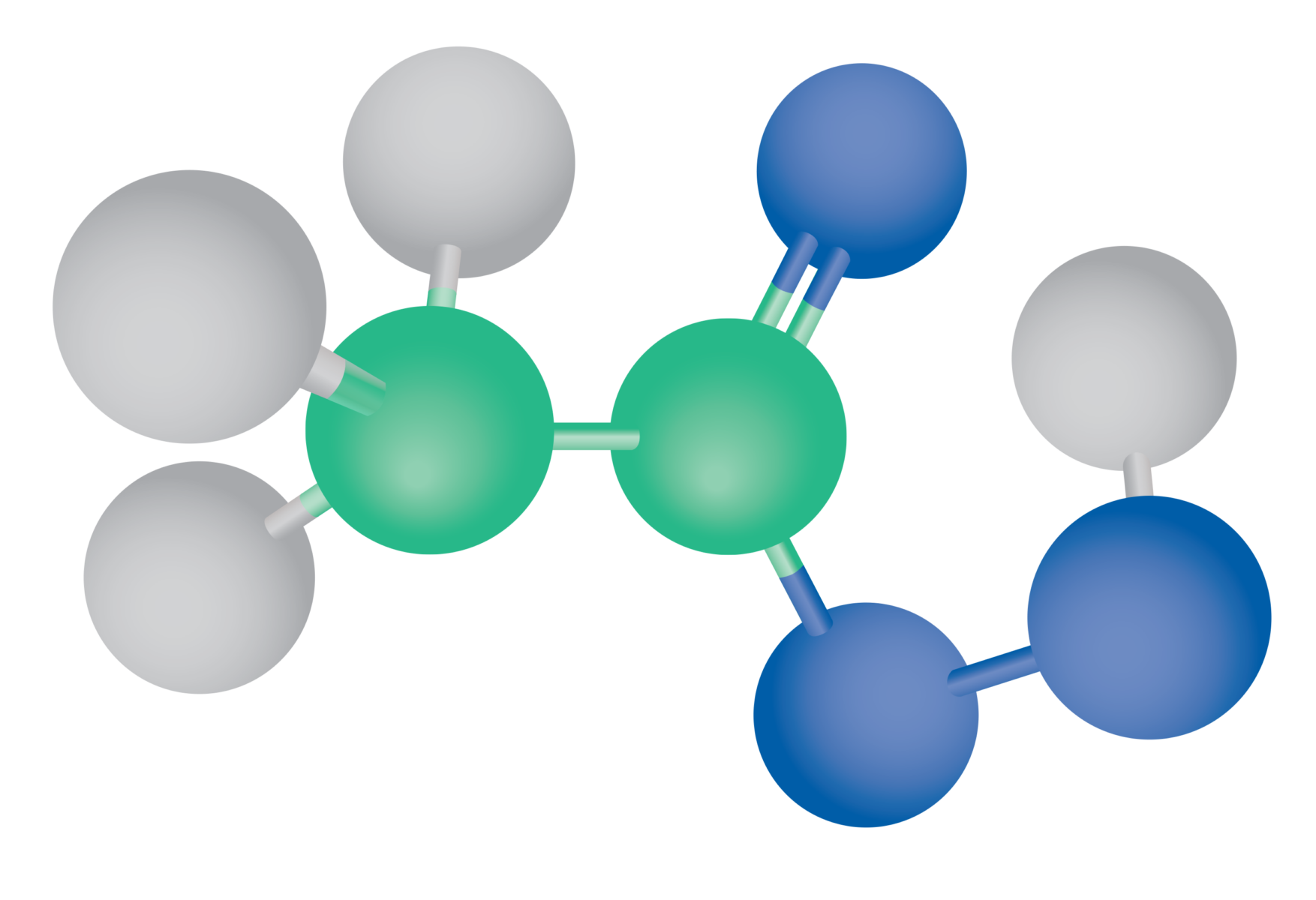

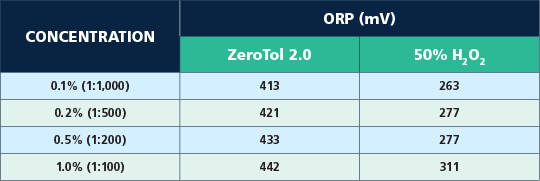

Hydrogen peroxide (H2O2) has oxidizing power that produces results, but when hydrogen peroxide pairs with glacial acetic acid it creates an even more powerful and stable compound with capabilities that far exceed those of hydrogen peroxide working alone. The oxidizing properties of chemical compounds are

compared through their thermodynamic “Standard Reduction Potential¹”, which is measured in solution using Oxygen Reduction Potential (ORP)². BioSafe Systems’ PAA imparts an ORP value twice that of 50% hydrogen peroxide at equal concentrations. Products based strictly on hydrogen peroxide have a drastically lower oxidation potential and weaker sanitation and disinfection capabilities. Straight H2O2 is highly reactive to various organic components and degrades in the presence of sunlight, which quickly breaks it down into oxygen and water without allowing an extended time for the proper efficacy. The table depicts the difference between ORP values of 2% PAA and 50% H2O2.

PAA is a highly versatile chemistry formulated through the reaction of hydrogen peroxide and glacial acetic acid. Formulated with stabilizers and adjuvants for optimal stability and performance. The resulting aqueous solution produces the ideal microbiocide eradicating target organisms on contact whether in the water, on plant tissue, or in the soil. BioSafe Systems’ PAA-based chemistry secures high oxidation potential resulting in damage to cellular structures and preventing resistance. We’ve proven over the course of our 25 years that our products have earned their position alongside traditional production methods and can be easily integrated into existing programs.

Manufacturing, Labeling & Certifications

BioSafe Systems works diligently to ensure consistent quality and performance of all our products by manufacturing the majority of our products at at facilities we manage ourselves. Of all the products we produce, 90% of them are compliant with organic standards and are OMRI-Listed. Each has gone through a rigorous registration process in accordance with the applicable state and federal regulations.

BioSafe Systems’ PAA products are manufactured in three state-of-the-art locations in the United States designed to carry our unique chemistry and handle the requirements of our operations for efficient shipping. Our facilities are consistently audited and annually inspected by OMRI, NSF, and the Rabbinical Council for Kosher certification. Our manufacturing locations process in dedicated chemical-only production facilities and operate under FDA’s Good Manufacturing Practices (GMP), prohibiting the consumption of potential allergen-containing foods and beverages in production areas and regulating employee hygiene practices.

Our products confirm applicable regulations under all applicable EPA (US Environmental Protection Agency), State, National Organic Program (NOP), and conform to Canada and Mexico regulations. BioSafe Systems maintains records of the quality and source of the products supplied and the materials used in the manufacturing of our chemistry. We use only the highest grade of ingredients and source as much of our materials locally in the United States as we can. Our PAA products’ ingredients do not contain, nor are they derived from, alcohol, animal byproducts, genetically modified ingredients, or any known food allergens. The facilities we use to manufacture our chemistry are not used to process any of these non-permissible items.

Specialized PAA Formulations

BioSafe Systems develops specific formulations for the most efficacious treatments depending on the application method and target. Varying hydrogen peroxide and PAA in concentrated products, we create diverse formulations that can be applied to different plant materials, growing mediums, or water sources to eradicate pathogenic organisms infesting operations from multiple avenues. Producing PAA this way gives the chemistry higher stability, making it easier to handle and ship to growers and farmers who need it. BioSafe Systems develops target-specific formulations by varying the active ingredients, which change the volume of PAA in a solution.

Our SaniDate® line of sanitizer and disinfectant solutions range from 1.36%-28% and each variation uses PAA’s oxidizing strength to do different jobs. The percentage of PAA in each product is based on the ratio of H2O2 to PAA, we adjust that ratio per product, and issue recommended rates to change the ppm, providing end-users with ideal concentrations to meet the unique challenges of the operation. The lower concentrations of PAA are used for the home and are all child and pet friendly for high-touch areas in communal locations. The SaniDate® 12.0 formulation with 12% PAA is a microbiocide labeled for use in high-volume irrigation water treatment applications. Its higher concentration controls pathogens at critical points in crop protection, crop quality, and food safety, and it’s a more economical alternative than common chlorine. With the 15% PAA concentration, SaniDate® 15.0 is highly effective for controlling odor and disinfection in wastewater applications.

Likewise, the SaniDate® 5.0, which contains 5% PAA, is used frequently to treat plant pathogens and a wide variety of human health pathogens, specifically for hard, non-porous surface applications. In the same wheelhouse with 2% PAA concentration, StorOx® 2.0 works similarly to extend shelf life and reduce spoilage of stored crops. It’s an effective chlorine alternative that won’t leave harmful residues. We’ve seen great success with this product in potato storage.

Similarly, other concentrations are designed and labeled specifically to control problems found in greenhouses and fields without leaving any toxic residue. Algaecide and fungicide products like our ZeroTol® 2.0 and OxiDate® 5.0 work effectively without the risk of resistance.

The family and employees supporting BioSafe Systems have been working with PAA for decades and we continue to learn about different formulations, innovate applications, and reach for new ways to implement our sustainable and effective chemistry in all our divisions with integrity and transparency.

“We apply StorOx 2.0 product into the pile and the benefits we see on that is that attacks any little wound or nick or any sort of blemish on the potato itself, seals it up nice, and keeps that Fusarium from coming in and basically decaying the potato over the course of the winter storage.”

– George Moyer, 2023, Potato Production Manager at Marginet Family Farm

*A chemical’s tendency to gain electrons and be reduced.

**An electronic measurement of the ability of a chemical substance to oxidize or reduce another chemical substance, specifically in this case, a measurement of sanitizer’s efficacy in water.